Today’s sheet metal sector requires machines configured with useful accessories and increased working area, capable of responding to the great variety of parts to be produced. Innovative and functional options, which facilitate the operator’s work in order to maintain operating margins without overburdening the company’s budget. Promecam press brakes are available in four different configurations: Celeris, Eclectica, Exacta, and Robusta. All are characterised by the robustness of the structure, which is dimensioned and modelled using Ansys FEM software.

Ideal for most applications, it is characterised by its 6-axis backgauge and hybrid hydraulic system with brushless motor.

For those who want a machine that is versatile and comfortable to use, even for the most complex parts thanks to its relative seventh axis and retractable supports.

With the unique IRIS PLUS angle control system, material variability is no longer a problem: perfect parts from the first to the last bend. Added to this is a backgauge with two independent turrets with three axes each, for the most complex parts.

For those who bend large thicknesses: high power and longer bending lengths mean that even large plates can be processed with ease.

CNC Step Rock 15″. X-R-Z1-Z2 4-axis backgauge.

Tool adapters with manual upper lever clamping for European type tools, manual lower clamping for 60 mm base tools.

LazerSafe LZS-2 safety system

| model | 110T3000 | 175T3000 | 250T4000 | 300T4000 |

|---|---|---|---|---|

| open height [mm] | 400 | 400 | 400 | 400 |

| stroke [mm] | 200 | 200 | 200 | 200 |

CNC Step Rock 17″. 5-axis X-R-Z1-Z2-Xrel backgauge. With pneumatic retractable supports. Hydraulic upper clamping for W-type tools, manual lower clamping for 60 mm base tools. LazerSafe IRIS safety system.

| model | 110T3000 | 175T3000 | 250T4000 | 300T4000 |

|---|---|---|---|---|

| open height [mm] | 600 | 600 | 600 | 600 |

| stroke [mm] | 400 | 400 | 400 | 400 |

CNC Step Rock 22″. 6-axis X1-X2-R1-R2-Z1-Z2 backgauge. Hydraulic upper clamping for W-type tools, manual lower clamping for 60 mm base tools. LazerSafe IRIS PLUS safety system.

| model | 110T3000 | 175T3000 | 250T4000 | 300T4000 |

|---|---|---|---|---|

| open height [mm] | 600 | 600 | 600 | 600 |

| stroke [mm] | 400 | 400 | 400 | 400 |

CNC Step Rock 17″. 4-axis X-R-Z1-Z2 backgauge. Hydraulic upper clamping for W-type tools, manual lower clamping for 90 mm base tools. LazerSafe LZS-2 safety system.

| model | 400T4000 | 500T5000 | 600T6000 |

|---|---|---|---|

| open height [mm] | 600 | 600 | 600 |

| stroke [mm] | 400 | 400 | 400 |

We use high-end components from leading manufacturers for our press brakes, such as: Step (IT), LazerSafe (AU), Givi Misure (IT), Rolleri (IT), Schneider (FR), Siemens (DE), Wila (NL), Yaskawa (JP), Rexroth (DE), Valqua (JP), Hiwin (TW), Fietz (DE).

Our machines also owe their reliability to a large number of quality controls at various stages of the production process.

Promecam press brakes are equipped with the unique WATT monitoring system. Thanks to a network of extremely sensitive sensors, we collect a large amount of data, which is then processed by sophisticated intelligent algorithms.

In this way, we monitor all the vital parameters of the machine and are able to detect many anomalies, even the most imperceptible ones. On-board AI technologies also allow us to detect and report any misuse of the machine such as overloads, crashes, collisions and other damage: protecting your investment has never been easier.

The WATT platform collects machine utilisation and energy consumption data, and presents it via an intuitive, information-rich dashboard. We can interface with MES and ERP and help you calculate machining times and energy costs accurately.

The backgauge of the press brakes is driven by brushless motors with recirculating ball screws to ensure high precision with low backlash. It is available in 2-, 4-, and 5-axis versions, as well as a 6-axis version with two independent turrets.

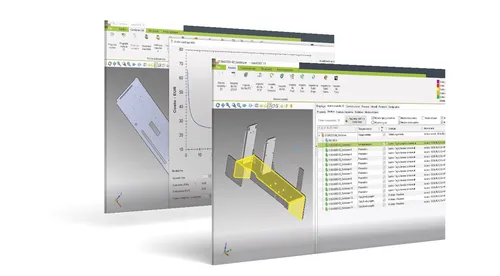

The press brakes of the Celeris, Eclectica, Exacta and Robusta series are fitted with CNCs from the Italian manufacturer Step Automation: advanced systems capable of handling 3D models and programs combined with a user-friendly graphic interface.

To reduce consumption and increase speed, the main pump is driven by a high-power brushless motor. The motor is controlled by a servo drive that drives it at optimised speed and torque according to the workload.

Our press brakes use the LazerSafe safety system. An advanced device that monitors the area around the punch and prevents accidents or damage. It is unique in that it can change speeds down to 0 mm from the sheet metal and automatically recognises boxed parts. Thanks to Bend Speed Management technology, it is also able to monitor the rotation speed of the sheet metal and thus be able to bend at speeds above 10 mm/s in compliance with regulations.

A distinctive feature of the Exacta equipment, this optical system uses profilometry combined with sophisticated algorithms to measure and correct the bend angle in real time. The result is parts that are always bent with maximum precision, without wasting time and material.

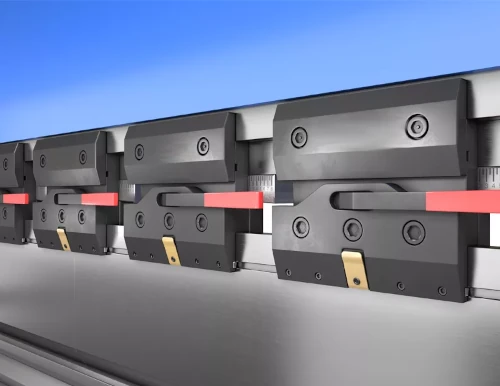

From traditional manual lever clamping to state-of-the-art hydraulic clamping for W-type tools: Promecam press brakes have a configuration for every need. Because every workshop has its own way of producing and combining investment and productivity.

Every machine needs the right software to operate at maximum capacity. That is why, through our partner Computes Group, we can offer you CAD, CAM, and Industry 4.0 solutions that combine high productivity with excellent investment value.