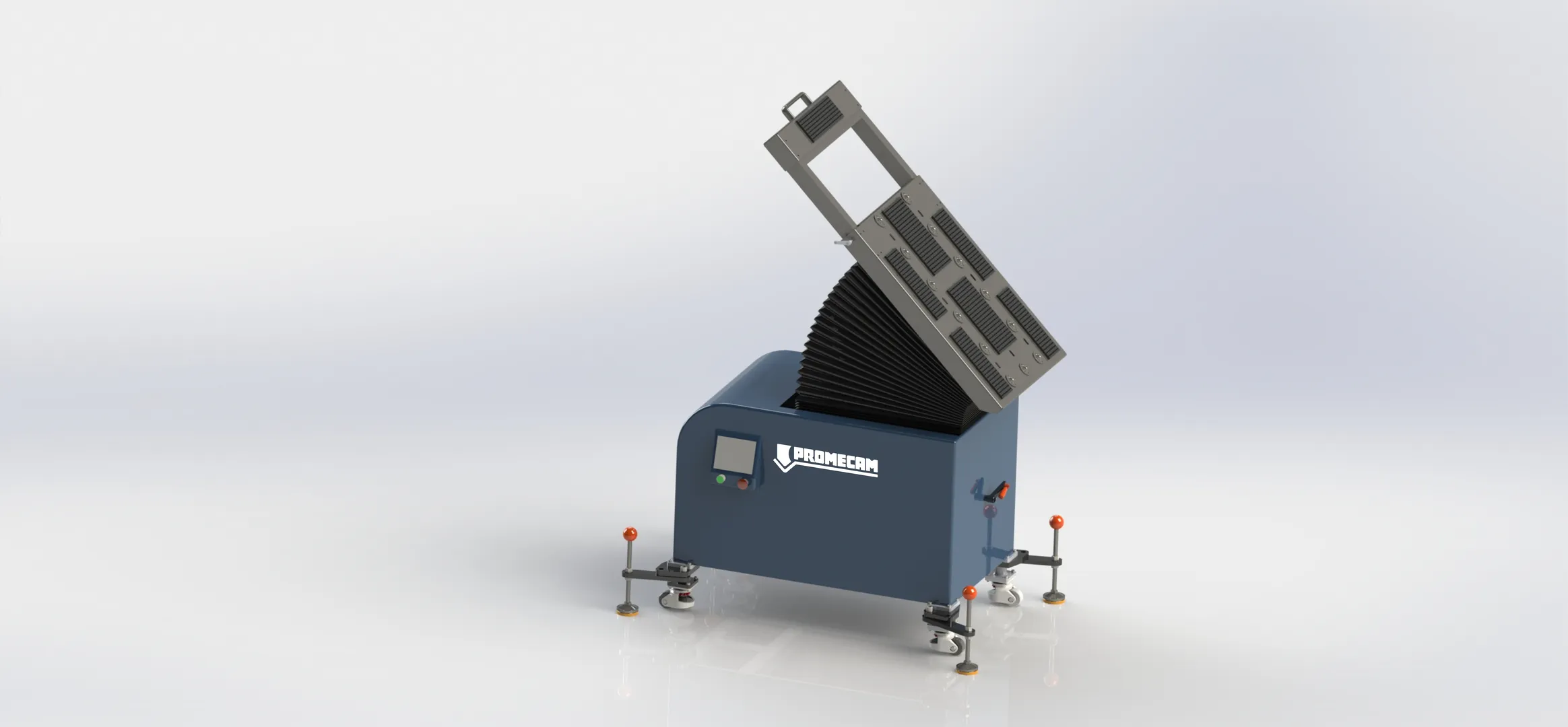

Atlas sheet metal followers are movable tables that support the rotation of the workpiece during the bending phase.

If not properly supported, very large and thin sheets can deform during the bending phase.

The followers support the sheet, preventing the phenomenon of counter-bending.

Supporting very large and heavy sheets may require two or more operators. The operation is very tiring on the musculoskeletal level.

The followers eliminate the physical effort required of the operator, reducing fatigue and the possibility of injury.

The number of operators required to perform the operation is also reduced, allowing it to be used for more productive purposes.

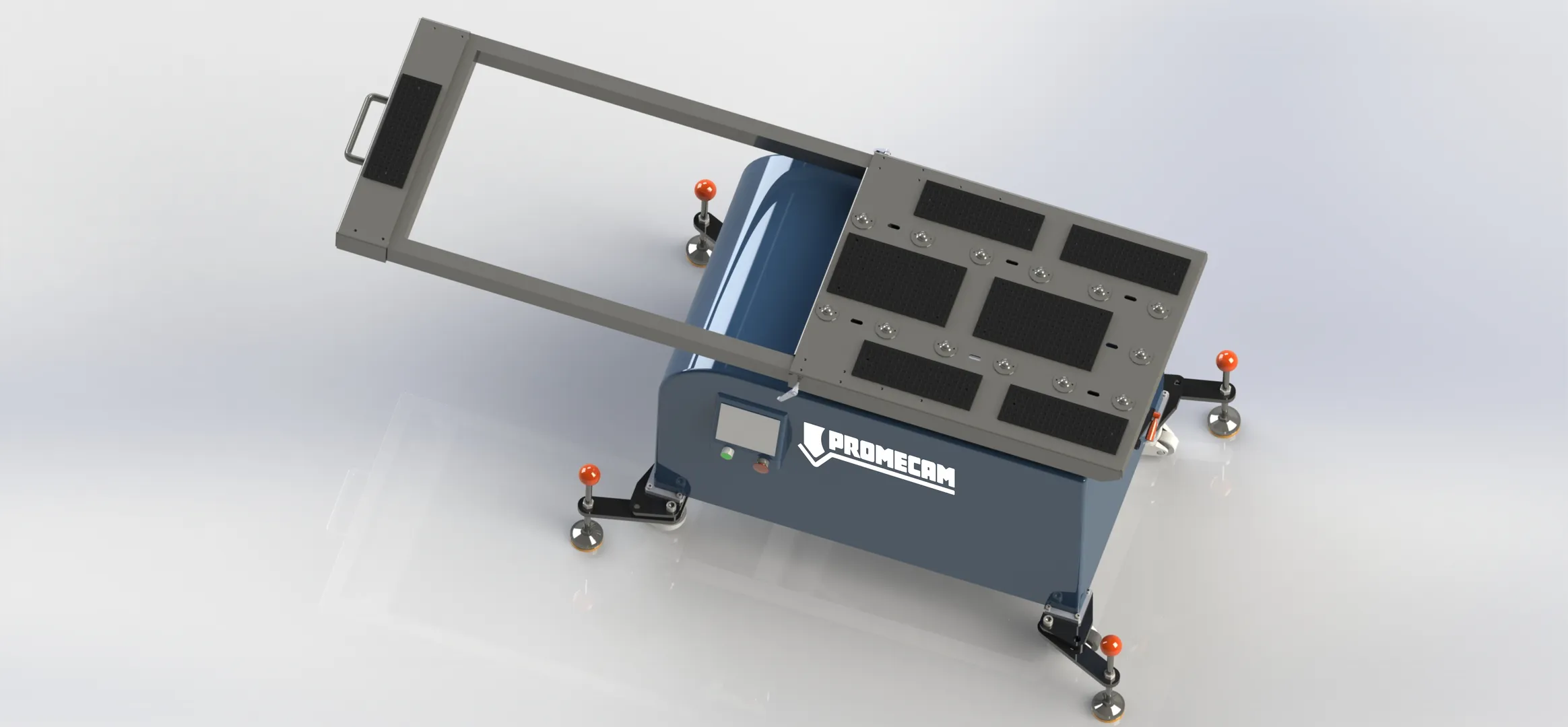

The table height can be realised to customer specifications according to the press brake characteristics.

| Model | Atlas 100 | Atlas 200 | Atlas 300 |

|---|---|---|---|

| Table width | 650 mm | 650 mm | 650 mm |

| Extended table width (optional) | 1700 mm | 1700 mm | 1700 mm |

| Open/closed table length | 1600 mm/1200 mm | 1600 mm/1200 mm | 1600 mm/1200 mm |

| Extended table length (optional) | 2200 mm | 2200 mm | 2200 mm |

| Maximum load at 1 m | 100 kg | 200 kg | 300 kg |

| Maximum rotation speed | 85 °/s | 40 °/s | 30 °/s |

| Positioning accuracy | ± 0,25 ° | ± 0,25 ° | ± 0,25 ° |

| Maximum angle of rotation | 75 ° | 75 ° | 60 ° |

| Minimum V-die width | 8 mm | 16 mm | 24 mm |

| Minimum table height (standard) | 940 mm | 950 mm | 1000 mm |

| R axis stroke | 180 mm | 180 mm | 180 mm |

| Overall dimensions | 1250×800×950 mm | 1250×800×950 mm | 1250×800×950 mm |

| Weight (approx.) | 400 kg | 500 kg | 600 kg |

| Power | 3,3 kW | 3,3 kW | 3,3 kW |

| Supply voltage | 230 Vac | 400 Vac | 400 Vac |

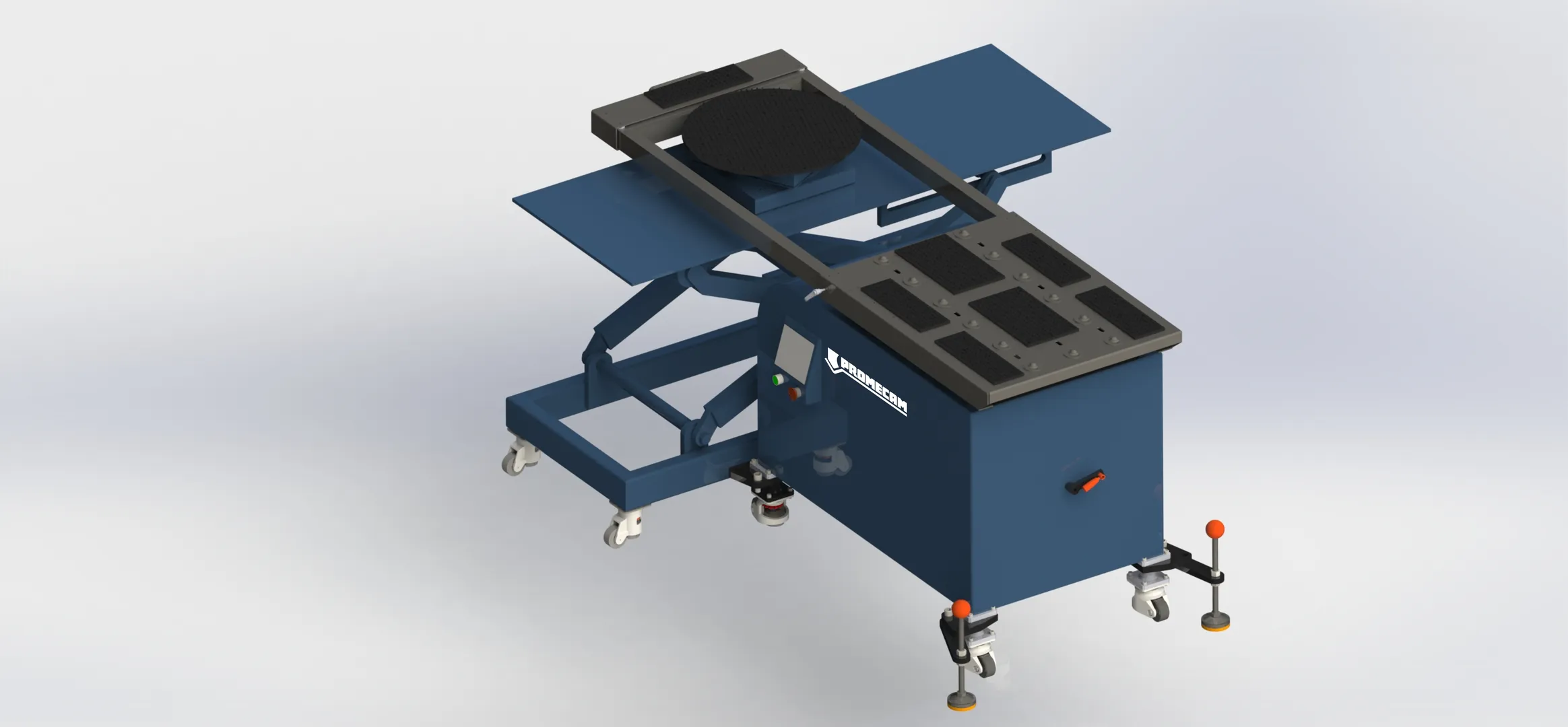

Promecam Atlas mobile sheet metal followers are compatible with any press brake model, of any tonnage and length.

The same sheet metal follower can be used on different machines within the same workshop, simply by moving it from one machine to another in a few simple operations.

The worktable can be customised in height up to a maximum of 1200 mm. The motorized R-axis (vertical) allows an adjustment of 180 mm to adapt to any die.

Added to this are some extremely useful optional extras, such as:

Thanks to the rotary table, even large sheets can be rotated effortlessly.

The maximum load capacity is 300 kg, to support even very heavy workpieces.

The support surface is covered with scratch-resistant brushes so as not to damage delicate materials such as pre-painted or polished.

The height is adjustable to adapt to the height of the die.

Our devices are the only ones on the market to be CE certified.

Some companies market similar products by mistakenly passing them off as ‘quasi-machines’, exposing the buyer to the risk of litigation.

Promecam’s sheet metal followers have passed tests related to the Machinery Directive for Low Voltage and Electromagnetic Compatibility devices.

Upon request, Promecam also offers the customer a certification service for the entire setup.

This will certify compliance with all regulations for the entire operator/ sheet metal follower system. An extra safeguard for both the owner and the operator.