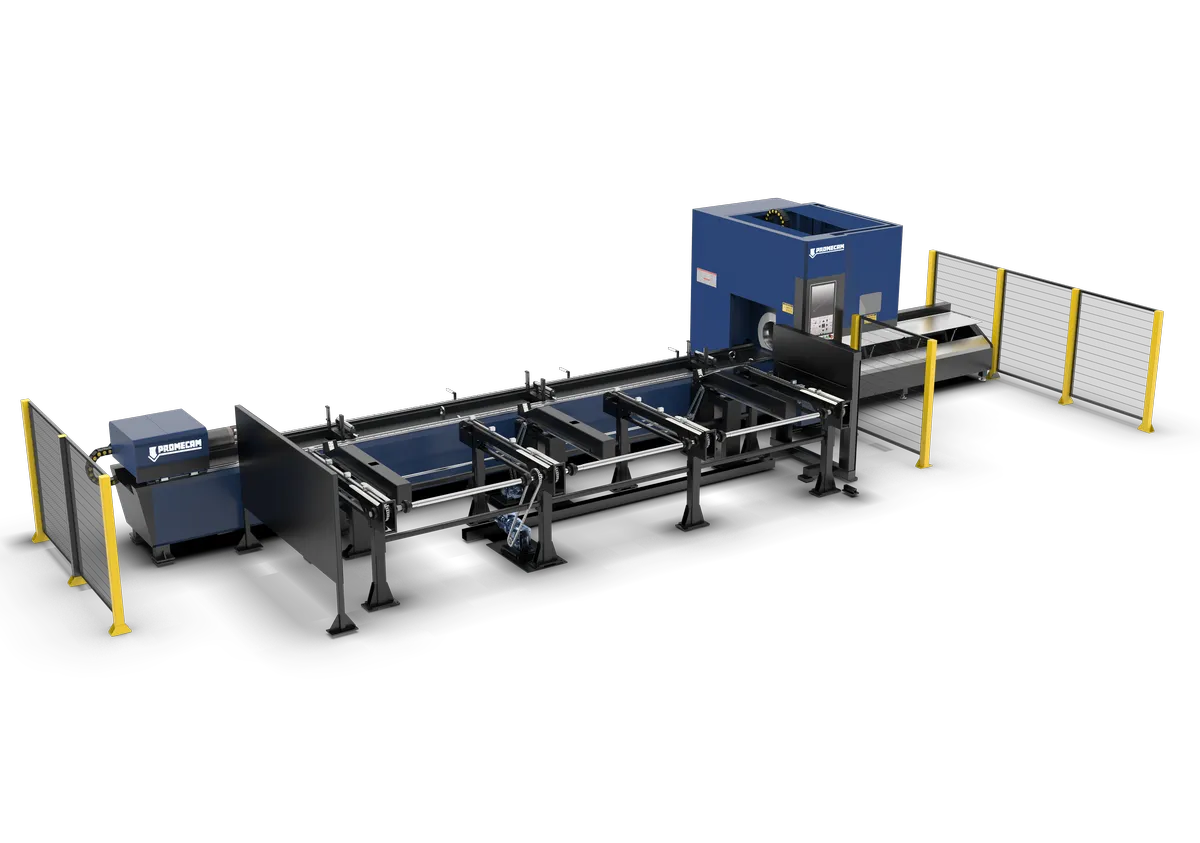

Tube processing is the one that shows the greatest potential for expansion. Don’t be left out: with Promecam tube lasers you can access this niche market with a small investment. Robust, versatile machines that can also process profiles and bars. Automatic loading systems for tubes and profiles are also available here.

These are just some of our configurations. Contact us for any specific requirements or larger sizes.

| Model | 6160/3 | 6240/3 |

|---|---|---|

| Laser power [kW] | 3 | 3 |

| Input tube length [mm] | 6300 | 6300 |

| Maximum finished product length at outlet [mm] | 1500 | 1500 |

| Maximum diameter [mm] | 160 | 240 |

| X/Y axis positioning accuracy [mm] | ±0,05 | ±0,05 |

| X/Y axis positioning repeatability [mm] | ±0,03 | ±0,03 |

| Maximum X/Y axis speed [mm]. | 110 | 110 |

| Maximum spindle speed [rpm] | 150 | 120 |

| Maximum acceleration [g] | 1,2 | 1,2 |

| Maximum chuck load capacity [kg] | 100 | 300 |

| Machine weight [kg] | 4300 | 5500 |

| Remaining scrap [mm] | 50 | 50 |

| Type/model of CNC | CypCut 3000 | CypCut 3000 |

| Dimensions L×W×H [mm] | 11377×2423×2475 | 11383×2423×2600 |

| Tube outfeed support method | Variable groove support wheel (up to 1500 mm) | Variable groove support wheel (up to 1500 mm) |

| Tube outfeed support method [optional] | Floating table (up to 3000 mm) | Floating table (up to 3000 mm) |

| Semi-automatic loading system | Optional | Optional |

| Fully automatic loading system | Optional | Optional |

These are just some of our configurations. Contact us for any specific requirements or larger sizes.

| Model | 6240/3 Max | 6350/6 Max | 9350/6 Max | 12350/12 Max |

|---|---|---|---|---|

| Laser power [kW] | 3 | 6 | 6 | 12 |

| Input tube length [mm] | 6300 | 6300 | 9300 | 12300 |

| Maximum finished product length at outlet [mm] | 6000 | 6000 | 6000-9000 | 6000-9000-12000 |

| Maximum diameter [mm] | 240 | 350 | 350 | 350 |

| X/Y axis accuracy [mm] | ±0,05 | ±0,05 | ±0,05 | ±0,05 |

| X/Y axis repeatability [mm] | ±0,03 | ±0,03 | ±0,03 | ±0,03 |

| Maximum X/Y axis speed [mm] | 110 | 110 | 110 | 110 |

| Maximum spindle speed [rpm] | 120 | 120 | 120 | 120 |

| Maximum acceleration [g] | 1.5 | 1.5 | 1.5 | 1.5 |

| Maximum chuck load capacity [kg] | 500 | 600 | 800 | 1000 |

| Machine weight [kg] | 14000 | 16000 | 19000 | 25000 |

| Remaining scrap [mm] | 0 | 0 | 0 | 0 |

| Type/model of CNC | CypCut 5000 | CypCut 5000 | CypCut 5000 | CypCut 5000 |

| Dimensions L×W×H [mm] | 16100×3080×3650 | 16100×3080×3650 | 19100×3080×3650 | 22100×5000×2560 |

| Tube outfeed support method | floating table | floating table | floating table | floating table |

| Semi-automatic loading system | Optional | Optional | Optional | Optional |

| Fully automatic loading system | Optional | Optional | Not available | Not available |

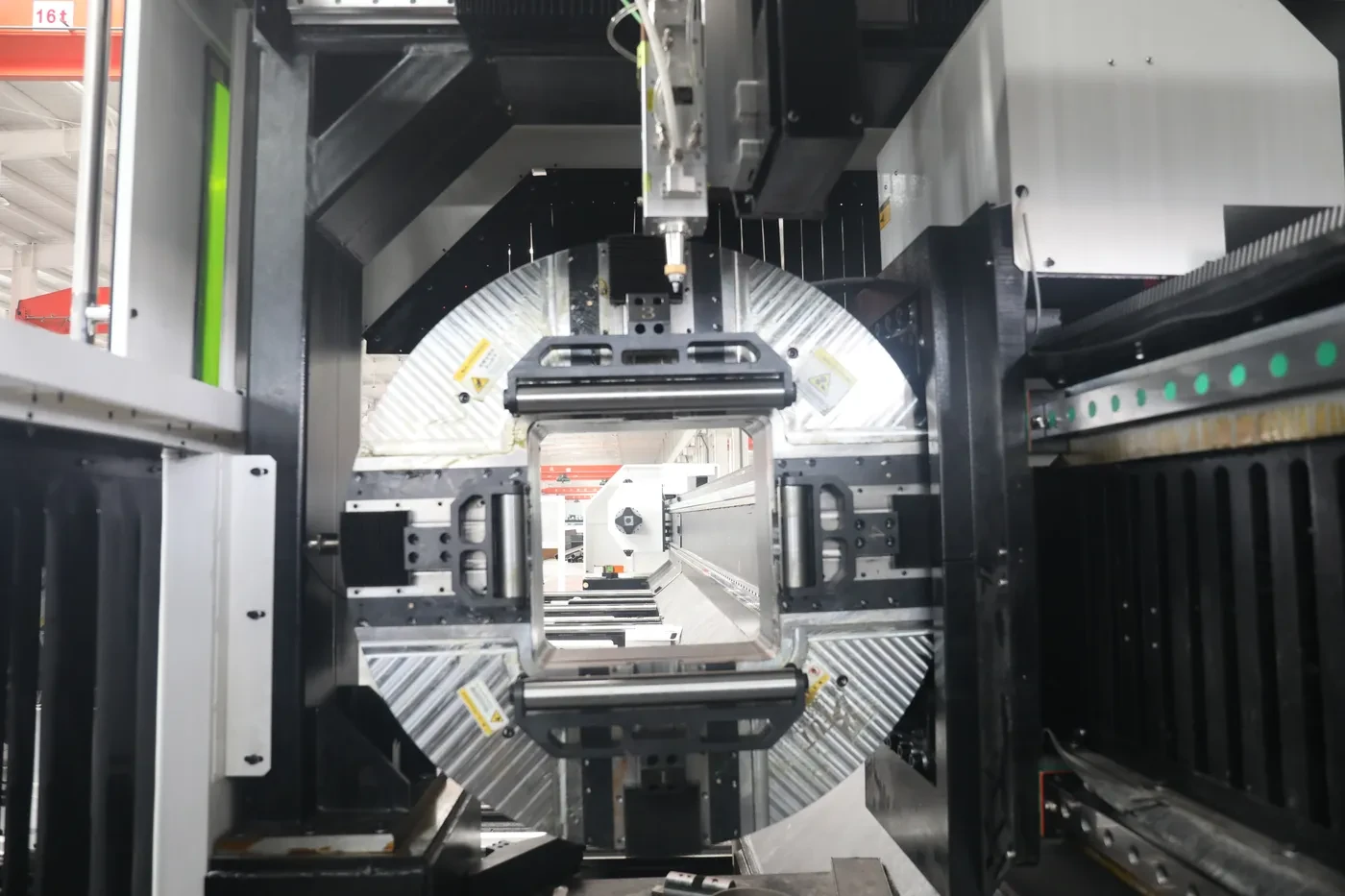

Fulgor Tube is available in various sizes and versions, from the simplest machines without an automatic loader, to more complex three-spindle machines such as the Max series.

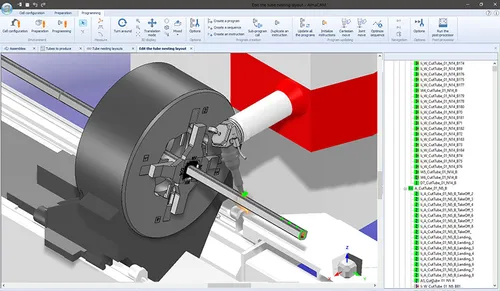

Advanced drawing, nesting and CAM programming suites offer the possibility to create an effective link between the technical department and the production department. Thanks to collaboration with leading Italian software houses, you have complete control over your laser tube cutting machine.

Parallel to the data flow from the design phase to production, we introduce a feedback flow on the parts produced and processing times. This constitutes a real source of valuable information for the drafting of quotations and identification of critical points.

Upgrade your laser tube cutting plant to a maximum with automatic loading systems for bars and profiles. Eliminate complex and tiring manual loading operations and increase the profitability of your production.

By partnering with renowned integrators and industry leaders, we can provide systems and automation solutions designed to optimise the efficiency of your machine.

The Fulgor Tube laser cutting system is built using excellent quality components, including:

The Fulgor Tube laser cutting production process is subject to strict quality controls according to the Promecam® Quality Protocol. To safeguard your investment, Fulgor is equipped with the sensor and Smart mAIntenance system WATT⚙️, capable of detecting numerous potential anomalies in advance.

If you want total and precise control over your equipment, the WATT⚙️ dashboard gives you access to information on electrical consumption, misuse, production times and much more. Interfacing with MES and ERP opens the door to Industry 5.0. More accurate operating costs, better on-time delivery, less inefficient utilization.

Contact us to discover our artificial intelligence capabilities.

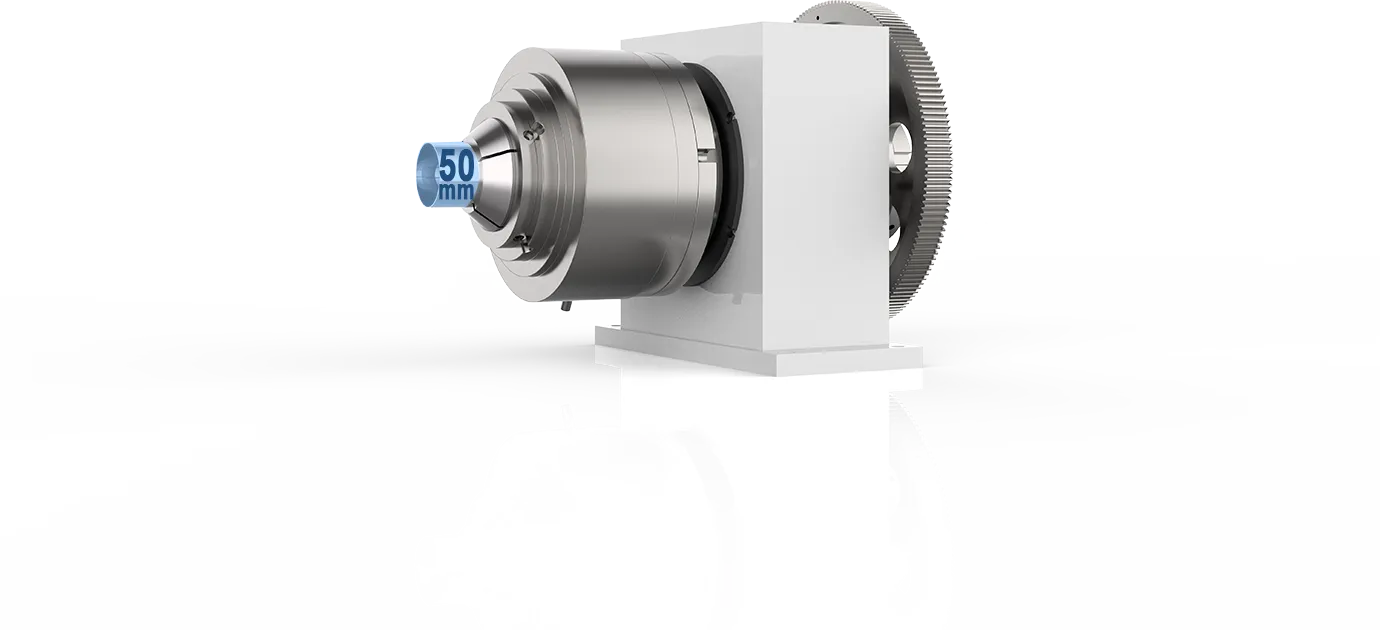

The Fulgor Tube laser cutting machine has a minimum processing length of only 50 mm: ideal for working efficiently and with minimum waste.

And with the three-chuck machines, you can process the entire length of the tube, without scrap.

The Bevel function is also available for inclined cuts on tubes and beams.

Chucks of our machines are designed according to the type of profiles or tubes you are going to cut, to guarantee maximum productivity.

The Bevel function is also available for inclined cuts on tubes and profiles.

We have chain or belt loaders, which can position the bars in the feeder without damaging them. Ideal if you are working with thin tubes or profiles or with delicate surface finishes.