Our Spira series press brakes are designed for sustainability. They do not use hydraulic oil, reducing environmental pollution and purchase and disposal costs. The absence of oil eliminates variability caused by temperature, ageing, hygroscopicity, etc. The servomotors only operate during the bending phase, so the machine has very low energy consumption when on standby.

All machines have two axes (Y1-Y2) and are equipped with 4-axis backgauge (X-R-Z1-Z2).

| Model | Spira 35/1350 | Spira 50/1650 | Spira 70/2050 | Spira 70/2500 |

|---|---|---|---|---|

| tonnage [t] | 35 | 50 | 70 | 70 |

| length [mm] | 1350 | 1650 | 2050 | 2500 |

| distance between side frames [mm] | 1300 | 1300 | 1700 | 2000 |

| throat [mm] | 150 | 210 | 300 | 300 |

| stroke [mm] | 180 | 180 | 200 | 200 |

| adapter/bench open height [mm] | 410 | 410 | 430 | 430 |

| X axis stroke [mm] | 400 | 400 | 600 | 600 |

| R axis stroke [mm] | 150 | 150 | 150 | 150 |

| Y1-Y2 axes power [kW] | 2×8,6 | 2×16 | 2×21 | 2×21 |

| Average power [kW] | 2,3 | 2,4 | 2,4 | 2,7 |

| dimensions L×W×H [mm] | 2300×1650×2200 | 2600×1900×2200 | 2680×1610×2560 | 2990×1610×2545 |

| Weight [kg] | 4000 | 5000 | 6250 | 6500 |

| crowning | no | no | no | mechanical |

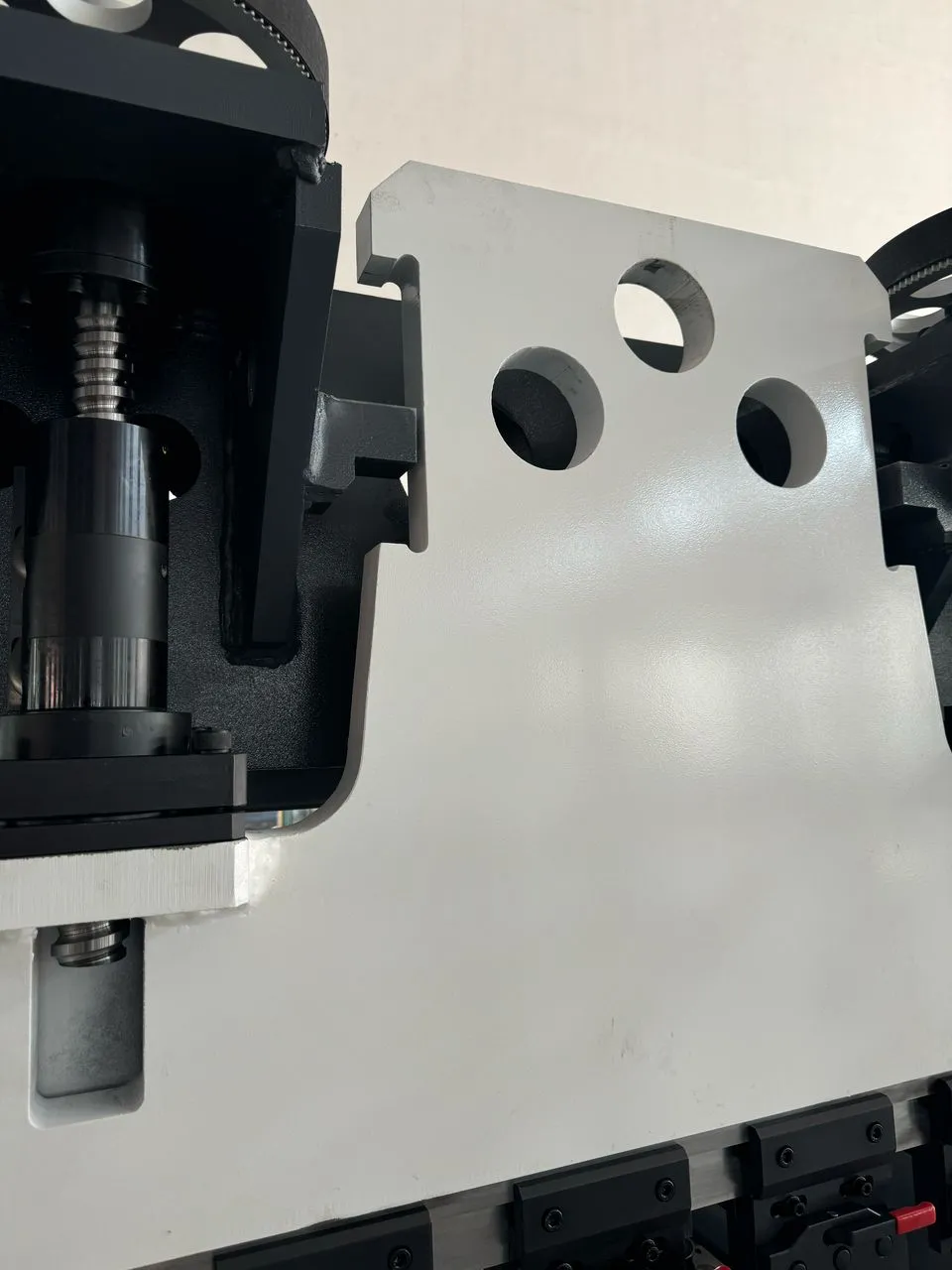

Servo-drive control ensures high up and down speeds, consistent repeat accuracy and high production efficiency. Their main features include:

Our dual servo approach controls the Y1 (left ram) and Y2 (right ram) axes using powerful 4000 rpm servo motors. This design guarantees high speed, precision and optimised cost management.

Components used:

Our Spira series press brakes are designed for sustainability. They use no hydraulic oil, reducing environmental pollution and the costs of purchase and disposal. The absence of oil eliminates variability due to temperature, ageing, hygroscopicity, etc. The servomotors only act during the bending phase, so the machine has very low standby power consumption.

Equipped with CNC systems from Step Automation, our press brakes offer power and ease of operation. They can be interfaced with CAM and MES, guaranteeing flexible and optimised management even in the context of Industry 4.0.

The Spira series press brakes are equipped with CNCs from the Italian manufacturer Step Automation: advanced systems capable of handling 3D models and programs combined with an easy-to-use graphical interface.

Many options allow the functionality of the CNC and offline software to be adapted to the customer’s specific needs.

The new generation of ROCK controls offers high performance programming and press brake management. The eye-catching Made in Italy design and the high quality of all construction details guarantee prestigious performance and long product life.

Ready for Industry 4.0 thanks to functions for production management, maintenance and remote programming and supervision.

The LazerSafe LZS-2 safety system is an advanced solution for protecting press brake operators. This system uses a laser light ‘barrier’ that surrounds the danger zone of the punch, detecting any obstacles. If the operator or an object enters this protected zone, the machine stops automatically.

The most important technical parameters of the LazerSafe LZS-2 safety system, which define its effectiveness and application, include:

Promecam press brakes are equipped with the WATT maintenance and consumption control platform: a proprietary system that constantly monitors the operation of key components. This allows us to monitor all vital machine parameters and detect many anomalies, even the most imperceptible. We can then intervene to resolve the problem before it causes a loss of quality or machine downtime. WATT technologies also allow us to detect machine misuse such as overloads, shocks, collisions and other damage: protecting your investment has never been easier.

The WATT platform, via an easy-to-read dashboard, provides all the data on machine utilisation rate, consumption efficiency, and energy cost for any time interval. By interfacing with the MES you can know the real cost of your products precisely.