Mercurius guillotine shears are the ideal choice for achieving precise cuts without damaging the surface of materials such as pre-painted or galvanised sheet metal.

Our shears offer an economical and highly efficient solution compared to more advanced technologies such as laser or plasma cutting. With low operating costs, they are the optimal choice to maintain high cutting quality without burdening the budget.

Mechanical cutting without heat input does not damage the surface, oxidise the metal or alter the crystalline structure. As a result, guillotine shears leave the surface intact and preserve the mechanical and chemical properties of high strength steels. Even delicate materials such as galvanised steel or pre-painted sheet metal can be cut with impeccable results.

| Model | 0630 | 1230 | 2530 |

|---|---|---|---|

| Max S275 thickness | 6 mm | 12 mm | 25 mm |

| Nominal cutting length | 3000 mm | 3000 mm | 3000 mm |

| Model | 0640 | 1240 | 2540 |

|---|---|---|---|

| Max S275 thickness | 6 mm | 12 mm | 25 mm |

| Nominal cutting length | 4000 mm | 4000 mm | 4000 mm |

| Model | 0660 | 1260 | 2560 |

|---|---|---|---|

| Max S275 thickness | 6 mm | 12 mm | 25 mm |

| Nominal cutting length | 6000 mm | 6000 mm | 6000 mm |

Thanks to the WATT system, we monitor the behaviour of your guillotine shear from various points of view. Through the WATT dashboard, you can view consumption trends and your machines’ real utilization rate. You will also receive real-time alerts in case of anomalies or misuse.

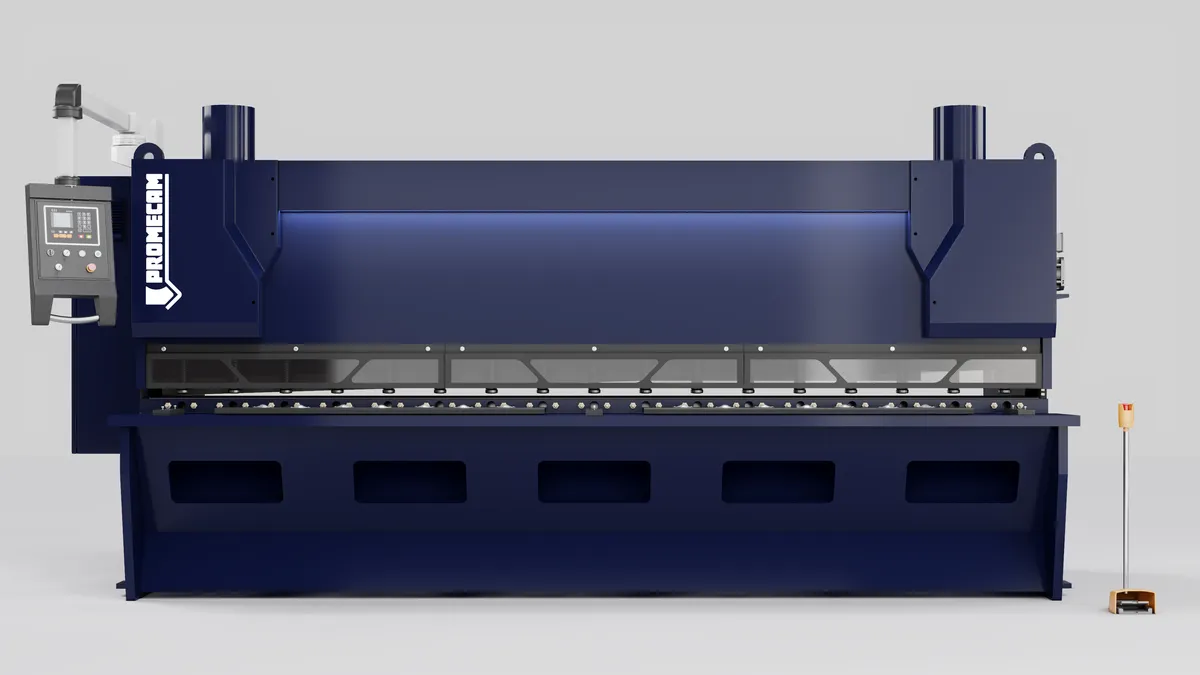

Promecam guillotine shears feature a rigid frame designed to minimise deflection under load. The machine is welded with advanced welding equipment and robotic technology. To improve mechanical properties, reduce deformations and improve overall stability and durability, the machine undergoes a high-temperature stress relief process.

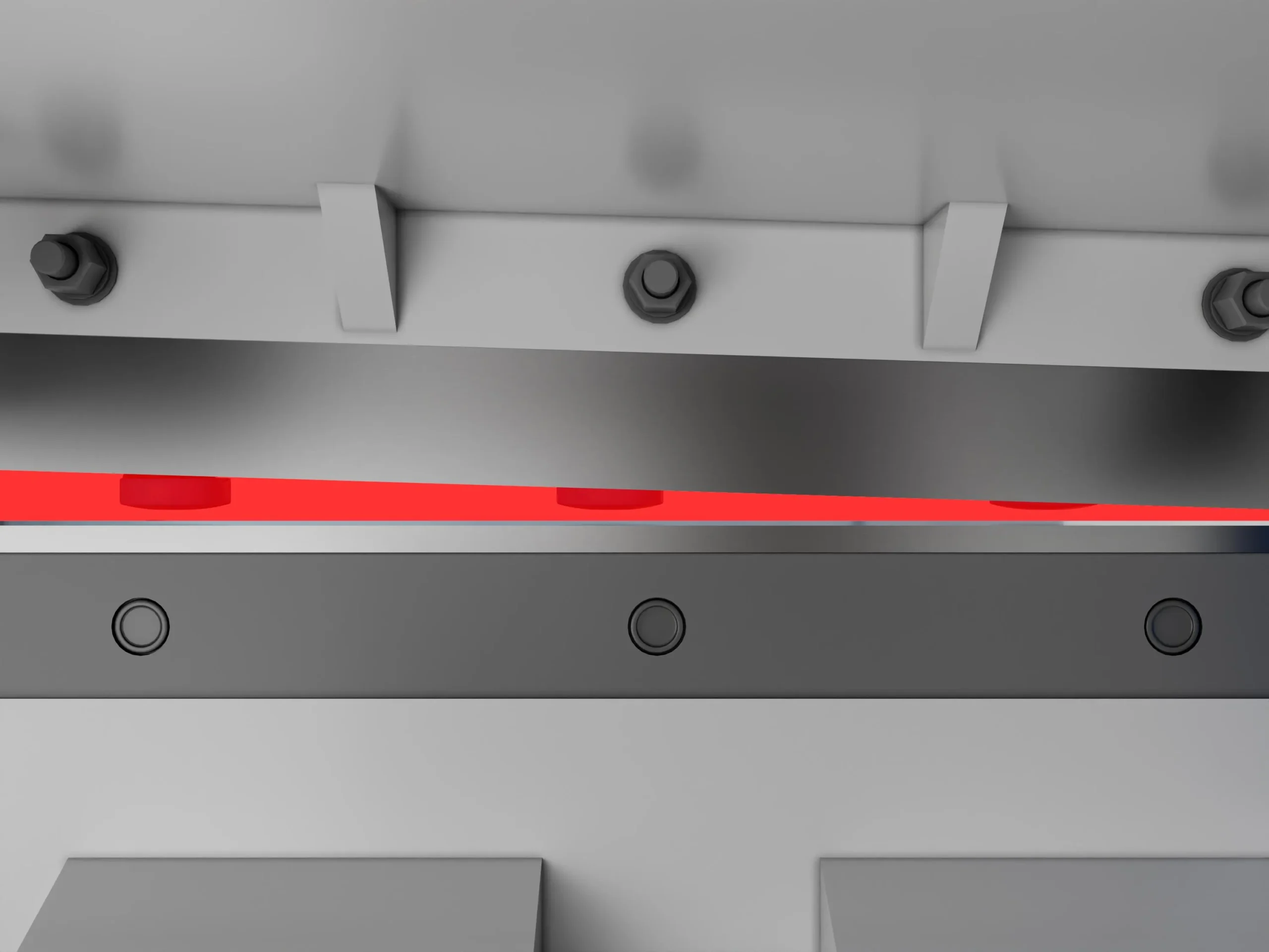

Motorised clearance adjustment allows the cutting process to be optimised for different materials and thicknesses to be sheared.

The cutting angle is CNC-adjustable to suit the characteristics of the sheet metal.

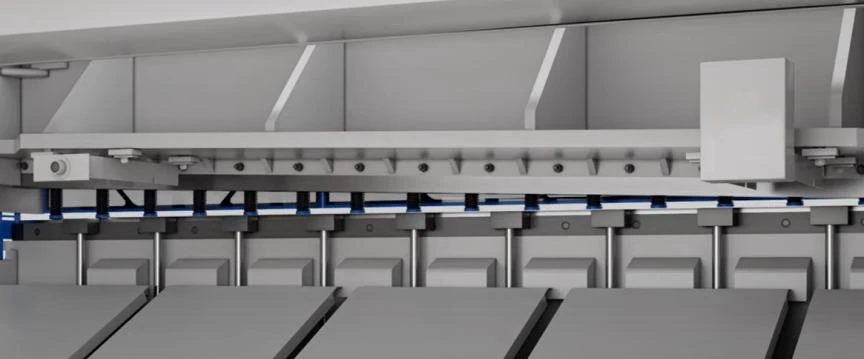

Concealed rear support to facilitate positioning of the sheet metal and increase the stability of the workpiece.

In the Type 2 pneumatic support system for thin sheet metal, it is not only possible to make the sheet more stable by lifting the material first, but it is also possible to lift the material after the sheet has been cut, to protect the cut sheet and increase work efficiency.

The compact design and user-friendly interface make these shears ideal for various industrial applications. Their versatility makes them suitable for production workshops and metal machining, ensuring reliable performance and easy handling. EasyCut CNCs from the Italian company STEP Automation provide ease of use, great power and interfacing functionality.

Long, thin strips tend to twist due to stresses within the sheet metal. The anti-twist system of a shear is a crucial mechanism designed to maintain the integrity of the material during the cutting process. By preventing the material from twisting, it guarantees precise cuts, consistent dimensions and defect-free end products.

A hydraulic piston system located along the cutting line pushes the workpiece against the upper blade. These clamping devices exert sufficient pressure to counteract the twisting forces. As an essential component of many metalworking operations, the shear’s anti-twist system plays a key role in achieving precise, high-quality cutting results. The sheet remains more straight, even at higher cutting angles.

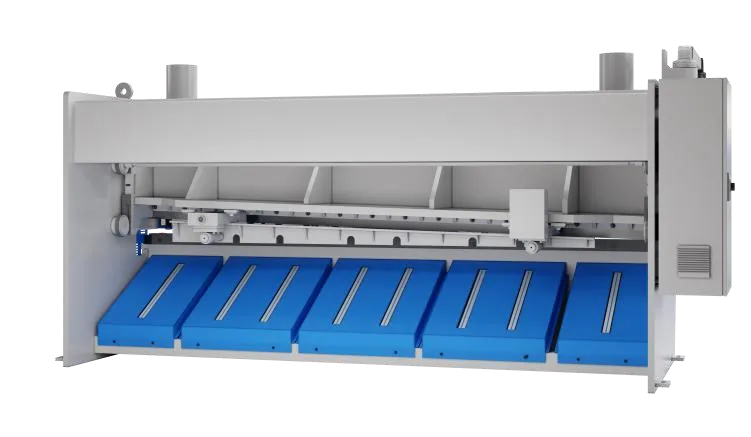

The front feeding table facilitates smooth and efficient feeding of material into the cutting area. It provides a flat, stable surface to position and align the workpiece before it undergoes the shearing process.

Driven by a double ball screw and linear guides, it ensures more precise feeding, the brush table with steel balls reduces scratches on the material surface. Pneumatic clamps, parallel to the work table, allow for convenient loading of the material.

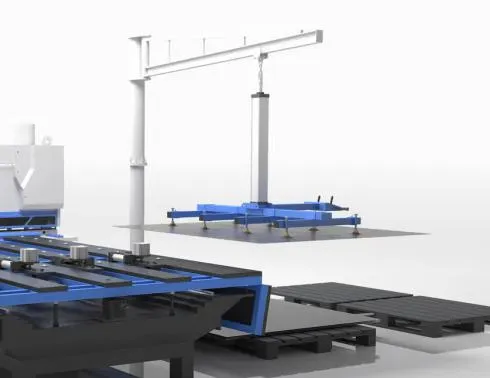

The suction cup loader is a specialised vacuum lifting device used to handle and manipulate large or heavy slabs. It uses vacuum suction to safely grip and lift plates without the need for manual clamping or gripping mechanisms.

The automatic stacking system optimises the post-cutting process. The cut sheets are automatically conveyed to the rear of the shear. A motorised device is positioned at the height of the strip evacuator and descends to allow the sheets to be stacked.

A motorised guillotine shear with servopump offers significant advantages in terms of efficiency, precision and energy consumption. This advanced technology allows precise control of the cutting process, ensuring optimal results for different materials and workpiece sizes. By improving both production efficiency and quality, this type of shear improves overall production operations.

Promecam’s guillotine shears are equipped with CE-compliant safety components, such as a certified safety module, rear infrared barrier, interlocked power switch on the electrical cabinet door, and safety microswitch on the front guard.