Reduced margins, skyrocketing material costs, smaller and smaller batches. Don’t find yourself a slave to an overly demanding investment, with the risk of working day and night to pay back the machine.

Today’s market forces companies to produce more and more varied and differentiated products. It is important to equip oneself with a machine that is sufficiently powerful, appropriately sized, but above all versatile.

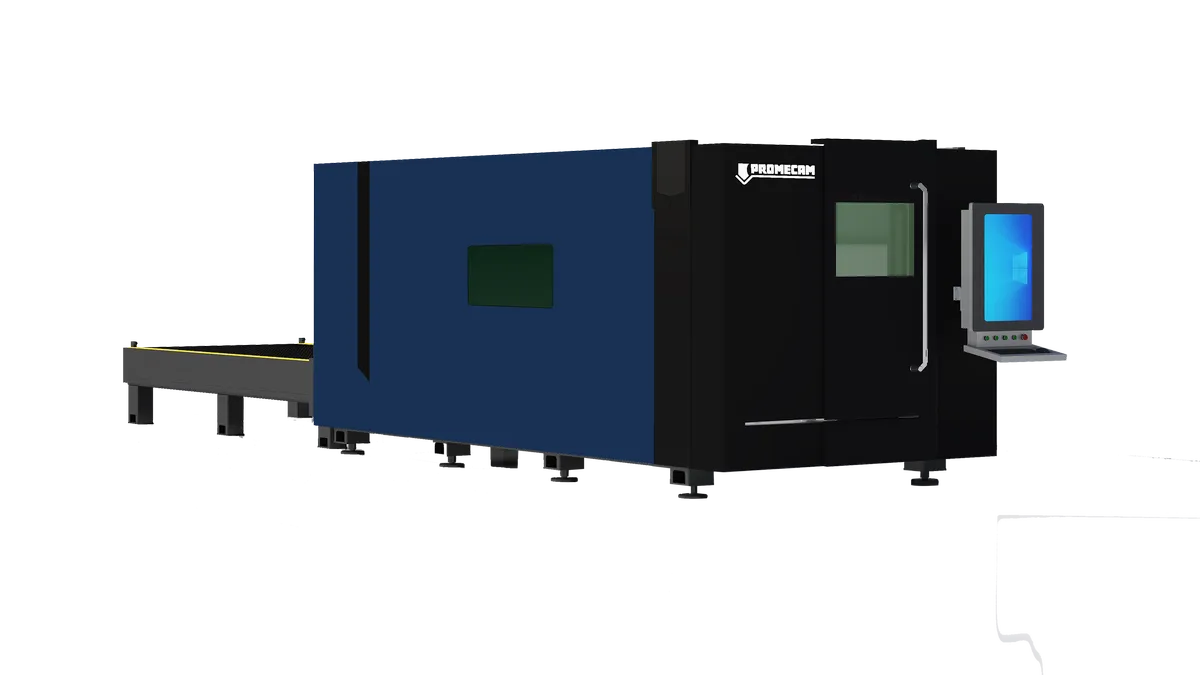

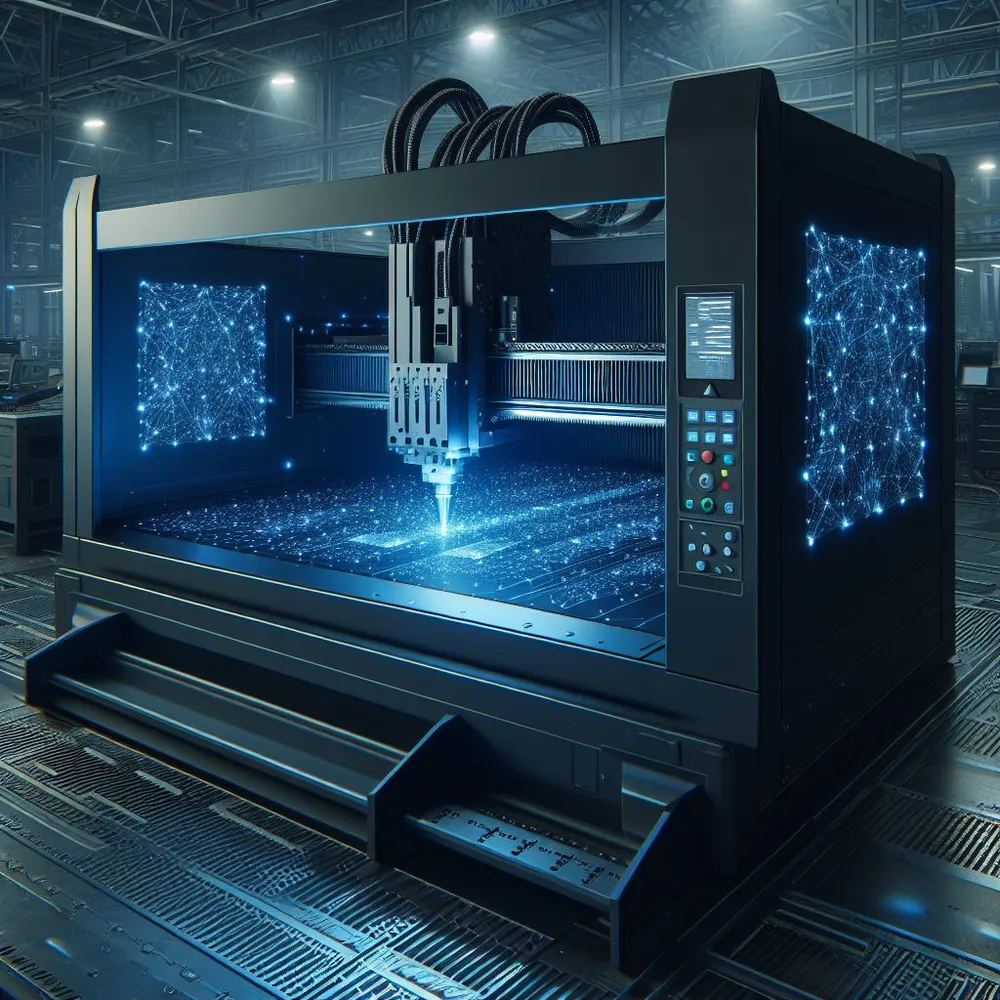

With Promecam’s Fulgor laser cutting machine, you are guaranteed an excellent price-quality ratio. All this with the security of an inspection and verification protocol at all stages of production, combined with AI-based predictive maintenance.

| Model | 1015/1,5 Mini | 3015/1,5 Mini | 3015/3 Mini | 3015/6 Mini |

|---|---|---|---|---|

| Bed [mm] | 1000×1500 | 1000×1500 | 3000×1500 | 3000×1500 |

| Power [kW] | 1,5 | 1,5 | 3 | 6 |

| Z-axis stroke [mm] | 90 | 150 | 150 | 150 |

| X/Y precision [mm] | ±0,03 | ±0,03 | ±0,03 | ±0,03 |

| X/Y repeatability [mm] | ±0,02 | ±0,02 | ±0,02 | ±0,02 |

| X/Y speed [m/min] | 60 | 120 | 120 | 120 |

| Max X/Y acceleration [g] | 0,6 | 1,2 | 1,2 | 1,2 |

| Capacity [kg] | 300 | 800 | 800 | 800 |

| CNC | CypCut 2000E | CypCut 2000E | CypCut 2000E | CypCut 2000E |

| Model | 3015/3 | 3015/6 | 3015/12 | 3015/20 |

|---|---|---|---|---|

| Bed [mm] | 3060×1515 | 3060×1515 | 3100×1530 | 3100×1530 |

| Power [kW] | 3 | 6 | 12 | 20 |

| Z-axis stroke [mm] | 300 | 300 | 345 | 345 |

| X/Y precision [mm] | ±0,03 | ±0,03 | ±0,03 | ±0,03 |

| X/Y repeatability [mm] | ±0,02 | ±0,02 | ±0,02 | ±0,02 |

| X/Y speed [m/min] | 130 | 130 | 160 | 160 |

| Max X/Y acceleration [g] | 1,5 | 1,5 | 2 | 2 |

| Pallet change time [s] | 17 | 17 | 17 | 17 |

| Capacity [kg] | 1000 | 1000 | 1000 | 1000 |

| CNC | CypCut 4000E | CypCut 4000E | CypCut 6000E | CypCut 8000C |

| Model | 4020/3 | 4020/6 | 4020/12 | 4020/20 |

|---|---|---|---|---|

| Bed [mm] | 4050×2020 | 4050×2020 | 4298×2007 | 4298×2007 |

| Power [kW] | 3 | 6 | 12 | 20 |

| Z-axis stroke [mm] | 300 | 300 | 345 | 345 |

| X/Y precision [mm] | ±0,03 | ±0,03 | ±0,03 | ±0,03 |

| X/Y repeatability [mm] | ±0,02 | ±0,02 | ±0,02 | ±0,02 |

| X/Y speed [m/min] | 130 | 130 | 160 | 160 |

| Max X/Y acceleration [g] | 1,5 | 1,5 | 2 | 2 |

| Pallet change time [s] | 17 | 17 | 17 | 17 |

| Capacity [kg] | 1600 | 1600 | 3000 | 3500 |

| CNC | CypCut 4000E | CypCut 4000E | CypCut 6000E | CypCut 8000C |

| Model | 6025/3 | 6025/6 | 6025/12 | 6025/20 |

|---|---|---|---|---|

| Bed [mm] | 6050×2530 | 6050×2530 | 6100×2530 | 6100×2530 |

| Power [kW] | 3 | 6 | 12 | 20 |

| Z-axis stroke [mm] | 300 | 300 | 345 | 345 |

| X/Y precision [mm] | ±0,03 | ±0,03 | ±0,03 | ±0,03 |

| X/Y repeatability [mm] | ±0,02 | ±0,02 | ±0,02 | ±0,02 |

| X/Y speed [m/min] | 130 | 130 | 160 | 160 |

| Max X/Y acceleration [g] | 1,5 | 1,5 | 2 | 2 |

| Pallet change time [s] | 17 | 17 | 17 | 17 |

| Capacity [kg] | 3000 | 3000 | 5000 | 6000 |

| CNC | CypCut 4000E | CypCut 4000E | CypCut 6000E | CypCut 8000C |

Available in various sizes and powers, with pallet changer and integrated suction system. Versatile machines with excellent value for money: ideal for those who want to upgrade their production, with maximum quality.

If you do not have large volume requirements, discover Fulgor Plate Mini: a compact, simple laser cutting machine, ideal for small batches. The cutting pallet is single side-extension for a smaller footprint. Ideal for conserving valuable workshop space!

For those who cut very small pieces but do not want to compromise on the effectiveness and speed of laser cutting, our Mini is also available in a 1000×1500 mm version, with an output power of 1500 W and 3000 W.

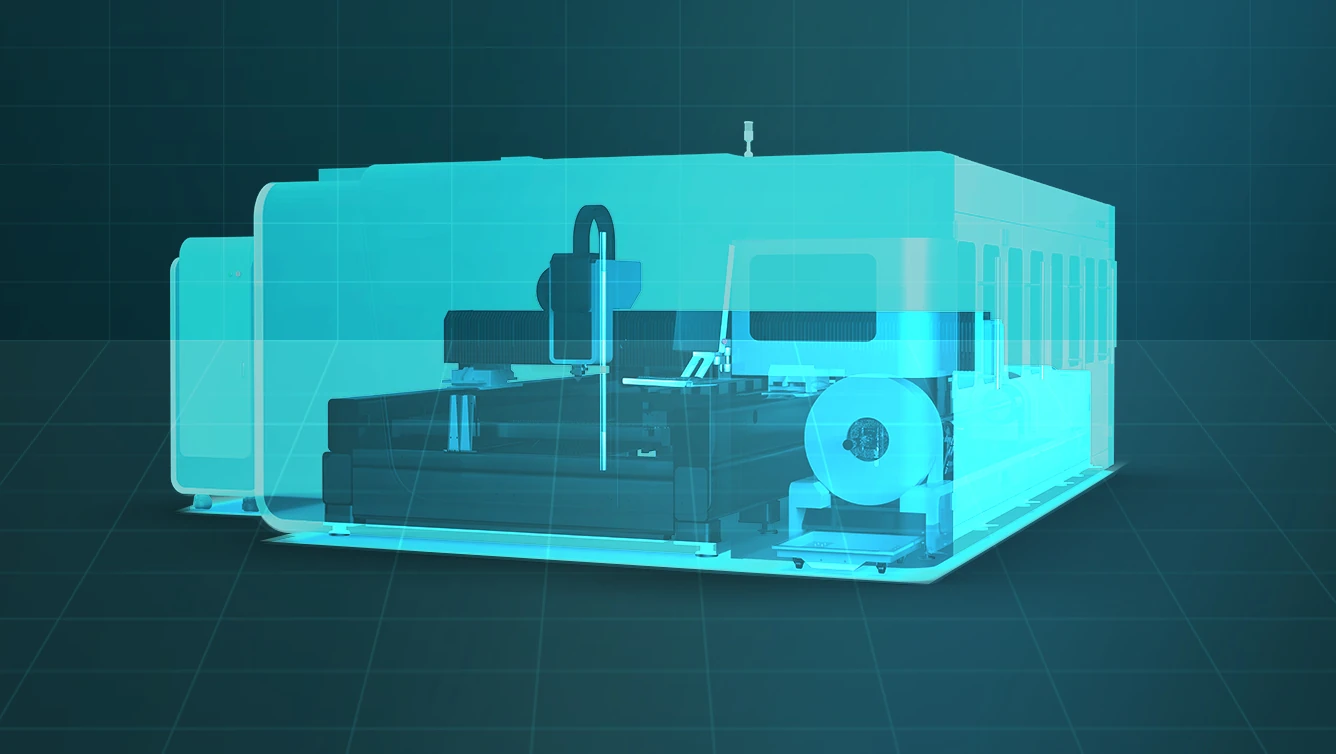

Laser cutting machine for plate and tube

Combined sheet/pipe laser cutting systems offer a versatile and productive solution for metalworking. By integrating laser cutting of flat sheets, tubes and profiles in a single machine, these machines guarantee

Ideal for the production of components for a variety of sectors, such as automotive, furniture, construction and agriculture, combined sheet/tube laser cutting systems represent an investment that pays off over time thanks to tangible benefits in terms of efficiency, flexibility and quality.

We can increase the productivity of your machine with:

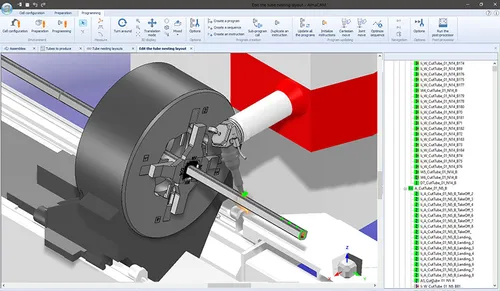

Advanced drawing, nesting, and CAM programming suites allow you to build a bridge between the technical office and production. With the collaboration of leading Italian software houses, you will have full control over your laser cutting machine.

Alongside the data flow from design to production, we provide a feedback flow on the parts produced and processing times. A veritable mine of information useful for making estimates and identifying bottlenecks.

Because anything that is unknown cannot be improved.

Turbo-charge your laser cutting equipment with automated loading and unloading systems and storage systems. Reduce unnecessary handling and increase the profitability of your production.

By collaborating with leading integrators and companies, we can provide systems and automations to maximise the efficiency of your machine.

Fulgor laser cutting is made from the highest quality components, such as

Fulgor laser cutting is subjected to strict quality controls and characteristics during all stages of production, according to the Promecam® Quality Protocol.

To protect your investment, Fulgor is also equipped with the WATT sensor and Smart mAIntenance system, which can detect many potential anomalies in advance.

If you want true 5.0 control over your plant, with the WATT platform you will have access to information on electricity consumption, misuse, production times and much more.

Contact us to learn more about our artificial intelligence capabilities.